Real-Time Data: A Game-Changer for Operations

Real-Time Data: A Game-Changer for Operations

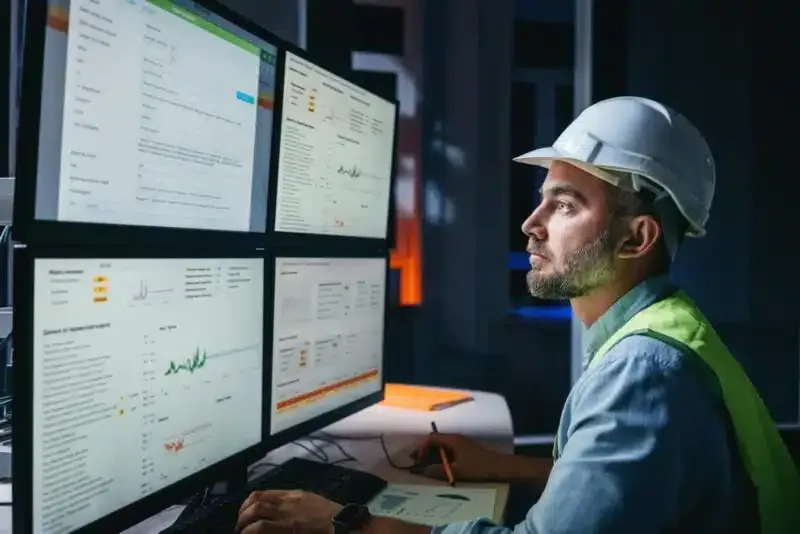

Manufacturing moves fast, but decision-making often lags behind without real-time data. Many companies still rely on outdated or incomplete data, making it difficult to respond to issues before they escalate. The result? Unplanned downtime, wasted resources, and missed opportunities for optimization.

Real-time data changes the way the game is played.

It gives manufacturers instant visibility into production, allowing them to catch inefficiencies, improve quality, and prevent costly disruptions. In today’s competitive market, waiting for end-of-shift reports or manually compiling performance metrics is no longer an option.

Live data empowers teams to act quickly, make informed decisions, and keep operations running efficiently.

This article explores why real-time data is essential, the risks of operating without it, and how Thrive’s platform helps manufacturers harness its full potential.

The Cost of Operating Without Real-Time Data

Manufacturers rely on efficiency; it is part of the job description, but delayed insights can hurt the entire team. Without access to live data, teams operate reactively, often discovering problems only after they have caused significant disruptions.

By the time reports are reviewed, inefficiencies have already cut into production schedules, leading to missed deadlines and increased costs. One major issue caused by delayed data is unplanned downtime. Minor faults—such as overheating components or declining performance—can go undetected when machines operate without real-time monitoring. By the time the issue is identified, the machine may have failed, requiring emergency repairs and halting production. A single breakdown can cost manufacturers thousands of dollars per hour in lost output, wasted materials, and labor inefficiencies.

The “High-Speed Packaging” Example

For example, imagine a high-speed packaging line running at full capacity. A minor misalignment in one of the rollers starts causing small tears in packaging materials. Operators may not notice the problem without real-time tracking until a batch inspection occurs hours later. By that time, hundreds of defective packages have been produced, requiring rework and delaying shipments. With real-time data, the system could have flagged the issue immediately, allowing operators to correct the misalignment before significant waste and downtime occurred.

Why This Matters

Manufacturers that lack intact insights are constantly playing defense, addressing issues only after they’ve caused damage. The ability to monitor operations eliminates guesswork, reduces delays, and ensures that production runs smoothly without costly interruptions.

Beyond quality control, downtime is one of the most expensive consequences of operating without real-time data. A single unexpected machine failure can halt an entire production line, leading to missed orders and frustrated customers. Without live insights, maintenance teams are often in reactive mode, fixing problems only after they’ve caused disruptions.

How Real-Time Data Transforms Manufacturing

Real-time data is a powerful tool that enables manufacturers to operate more effectively. Providing instant access to live insights eliminates guesswork and allows teams to make informed decisionsatthe moment, notinit!

Here’s how real-time data transforms manufacturing operations:

Improved Decision-Making

Manufacturing leaders often struggle to make the right decisions when working with outdated or incomplete data. By the time traditional reports are reviewed, the situation may have changed, leading to poor decision-making.

With real-time data, leaders can respond proactively to changing conditions on the shop floor. Whether it’s adjusting production schedules, reallocating resources, or addressing potential bottlenecks, having access to accurate, up-to-the-minute information ensures that every decision is based on current realities—not yesterday’s reports.

Reduced Downtime

Equipment failures and production jams are among the most costly challenges manufacturers face. Small issues can go unnoticed without real-time monitoring until they escalate into major disruptions that halt production.

Real-time data allows manufacturers to detect performance issues early, often before they lead to full machine failures. Predictive maintenance tools use live data to track machine conditions, alerting teams to unusual vibrations, temperature spikes, or slowdowns. By addressing these early warning signs, manufacturers can schedule repairs proactively and avoid expensive unplanned downtime.

Enhanced Quality Control

If not caught in time, manufacturing defects can quickly spiral into expensive waste and customer dissatisfaction. Traditional quality inspections often happen too late—after defective products have already moved through production.

With real-time quality monitoring, manufacturers can identify defects the moment they occur. Automated sensors and data analytics flag inconsistencies, allowing teams to make immediate adjustments and prevent further waste. This improves product quality, reduces rework costs, and protects brand reputation.

Operational Efficiency

Manufacturing efficiency relies on precise resource allocation and streamlined workflows. Without real-time insights, companies struggle to track cycle times, machine utilization, and material consumption, leading to bottlenecks, waste, and unnecessary labor costs.

Live data helps manufacturers optimize production schedules, balance workloads, and minimize material waste. Operators can adjust processes in real time based on actual production data, ensuring that every resource is used effectively. The result? Faster turnaround times, lower costs, and a more agile, responsive manufacturing operation. Real-time data is no longer a luxury—it’s a necessity for manufacturers looking to stay competitive. Providing instant visibility into every aspect of production enables smarter decisions, prevents costly disruptions, and drives continuous improvement across the shop floor.

How Thrive Helps You Harness Real-Time Data

Manufacturers need actionable insights that drive efficiency, reduce downtime, and improve quality. Thrive’s platform provides real-time visibility into every aspect of production, allowing teams to make informed decisions before issues escalate.

Instant Access to Real-Time Insights

Thrive eliminates the delays of traditional reporting by providing live data streams from the shop floor. Whether it’s machine performance, production rates, or quality control metrics, Thrive delivers instant visibility into key manufacturing processes. With a centralized dashboard, teams can monitor real-time performance, ensuring they always work with the most accurate, up-to-date information.

Real-Time Reporting for Smarter Decisions

Thrive’s real-time reporting capabilities enable manufacturers to track production efficiency, downtime, and quality trends as they happen. Unlike static reports that only provide historical data, Thrive’s live dashboards highlight performance trends immediately, allowing for faster corrective action. Teams can customize reports to focus on key metrics, ensuring they always have the insights needed to optimize operations.

The Future of Smart Manufacturing

Without instant visibility into production, manufacturers risk higher downtime, inefficiencies, and quality issues that drive up costs and reduce profitability. The most successful manufacturers are those that leverage real-time data to optimize operations, prevent disruptions, and improve decision-making. Live insights allow teams to spot inefficiencies before they become costly problems, respond to machine failures before they cause downtime, and ensure every resource is used effectively.

Conclusion: Why Thrive Is Essential

Thrive makes real-time manufacturing a reality. With instant reporting, mobile access, and automated alerts, Thrive gives manufacturers the visibility and control they need to stay ahead. Instead of reacting to problems after they occur, companies using Thrive can proactively manage production, reduce waste, and improve overall efficiency.

The future of manufacturing is smart, connected, and data-driven—and real-time insights are at the heart of it. Don’t let outdated systems hold your business back. Discover how Thrive can help you harness real-time data and transform your operations.